General Purpose & Slim Body Area Sensor NA2-N General Purpose & Slim Body Area Sensor NA2-N

|

|

» General Purpose & Slim Body Area Sensor NA2-N

Slim body 13 mm 0.512 in

Maximum sensing height 540 mm 21.260 in

| ※1 |

Conforming to EMC Directive |

| ※2 |

UL Recognition(Excluding 5 m cable length type) |

| ※3 |

Certified(NA2-□-K only) |

Features

■Notice of change for conforming to the revised CE Mark related directive

>> Click here

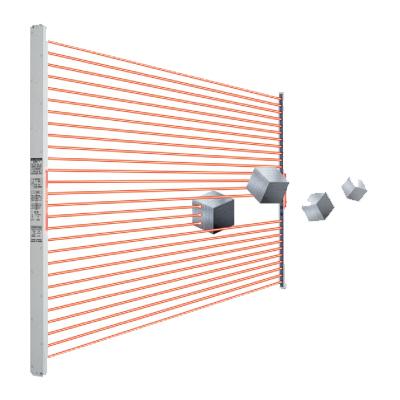

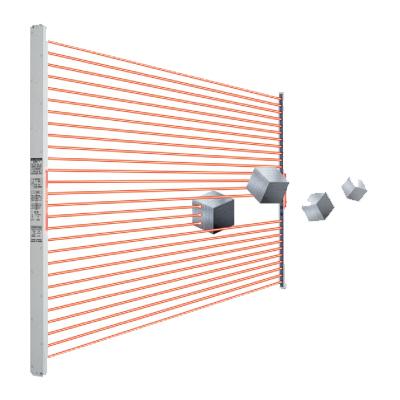

Maximum sensing height 540 mm 21.260 in (28 beam channels)

|

The thin resin case type area sensor has a sensing hight of 540 mm21.260 in (28 beam channels), a beam pitch of 20 mm 0.787 in(minimum sensing object of ø30 mm ø1.181 in), and sensing range of 5 m 16.404 ft to meet a variety of needs.

|

|

Slim body of just 13 mm 0.512 in thick

|

The slim-bodied NA2-N series fits right in your equipment, since it is only 13 mm 0.512 in thick and 30 mm 1.181 in wide. It dose not get in the way of your access to the machine.

|

|

6 types of sensing height

In addition to the conventional 12, 16, and 20 beam channel types, this new lineup includes 8, 24, and 28 beam channel types. A wide model variation is provided with sensing heights from 540 mm 21.260 in (28 beam channels) to 140 mm5.512 in (8 beam channels).

Globally usable

It conforms to the EMC Directive and obtains the UL Recognition. Products that has obtained the Korea's S-mark certification are available as well.

Moreover, PNP output type which is much in demand in Europe is also available.

Clearly visible wide job indicator

|

Both the receiver and the emitter feature job indicators, 102 mm 4.016 in wide, with red bright LEDs.

When the sensing output and the job indicator input are connected, the job indicator can be used as a large operation indicator.

|

|

Interference prevention for parallel installation

|

By setting different emission frequencies for two sensors, mutual interference can be prevented. There is no problem even when the sensors are parallel installed for wide detections area coverage. Moreover, the set frequencies can be identified by how many times the emitting indicators is light up.

|

|

Selectable lighting pattern

|

The operation of the job indicator can be selected using the operation mode selection switch.

|

|

Convenient test input (emission halt) function

|

Beam output can be stopped via the input of an external signal. This is an useful test input (emission halt) function when beginning operation.

|

|

Note: The photo above shows an 8 beam channels type. The operation mode selection switch is equipped on the left side of the main body for models other than the 8 beam channels type.

|

※1

※1 ※2

※2 ※3

※3